- HOME

- Introduction of our products

- Drum Flaker

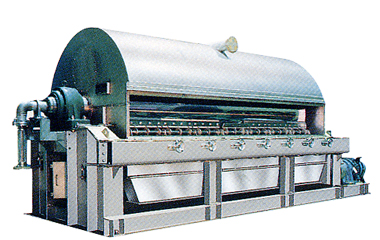

Drum Flaker

Drum flaker (F-1535-DP type)

A process for cooling and solidifying molten materials is often used in the chemical industry. However, if they are molded and solidified by batch operation, they cannot be treated in large quantity, and at the same time, lots of difficult problems arise in cracking, crushing, measuring, bag-packaging and other procedures. Thus, in cooling and solidifying the molten materials, the following advantages are brought by flaking them continuously:

1) Re-solubilization becomes easy. Working environments are improved compared with pulverized products.

2) Measuring and bag-packaging are easy, enabling automation.

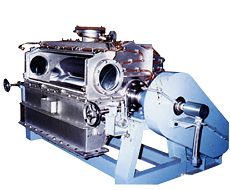

Test machines |

We have test machines always available, of which specifications are indicated below, and we are ready to carry out a test as needed and present the plan of equipment.

| Model | Atmospheric and open type |

|---|---|

| Drum dimension | ø400 × 500 L (surface area: 0.625m2) |

| Drum cooling method | Double drum cooling |

| Drum material | SUS304+hard chromium plate |

| Drum rotation speed | 0.2 ~ 15rpm |

| Available type | Any of the dip-feed, side-feed, top roll feed types can be tested. |

- Note: On the occasion of introduction, please provide the following information.

- 1. Melting point (solidifying point)

- 2. Dissolution temperature

- 3. Viscosity

- 4. Other chemical properties and handling precautions