- HOME

- Introduction of our products

- Concentrators

Evaporation/concentration

There are various methods for concentrating solutions. Such concentration methods are used individually according to the concentrations, components, and application purposes of solutions or they are used in combination. A method using ion-exchange resin, method using a nano-filter or reverse osmosis membrane, method using an electrodialytic membrane, and method using an evaporator are used in ascending order of concentration.

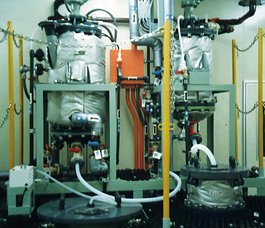

Various types of concentrators were also designed according to use application.

Such concentrators are classified into jacket type, calandria type, flash type, rising-film type, falling-film type, etc. according to the evaporation methods. Also, there are plate type, vertical tube type, horizontal tube type, etc. according to the shapes of the heating component, and further, an ejector type, heat pump (blower) type, multi-effect evaporator type, multi-stage flash type, etc. according to the energy-saving methods.

We design and manufacture systems that can be operated more efficiently and stably according to the liquid properties and purposes. We mainly adopt a rising-film type, falling-film type, and flash type.

To support energy saving, we mainly adopt an ejector type, heat pump type, and multiple-effect evaporator type.

Support for ECO (energy saving) |

- Steam compression type

- This type adiabatically compresses the total volume (100%) of evaporated steam using a compressor or blower such as a high-speed turbine and roots blower, and uses the heated steam as heating steam. This is the best energy saving method among the current technologies.

- Thermo-compression (ejector) type

- This type uses a steam-driven ejector to suck and compress a part of (approx. 65 to 20%) of evaporated steam, and heat the steam to use it as heating steam. Energy can be saved by the amount of steam suctioned.

- Multi-effect type

- Two-effect and three-effect types are mainly used for concentrators. In this method, steam consumption can be reduced by using steam generated by the first evaporator as heating steam for the next evaporator.

Double-effect evaporator type concentrator

High-purity evaporative concentration crystallizer