Dryers

Drum Dryers

Features

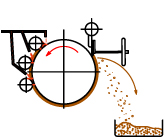

- Drum dryers are of conductive heat-transfer type. A heating medium (generally steam) is sent into the rotating drum (cylinder) and liquid material is fed on the heated drum to evaporate and concentrate, and concurrently the liquid material is stuck on the drum surface in the form of a film, then promptly evaporated and dried. Dried materials are scraped continuously with a stationary knife.

Drum dryers are roughly classified into an atmospheric type and vacuum type according to operating pressures, and also, they are classified into a double drum type, twin drum type, and single drum type according to the number of drums.

Further, the single drum type is classified into a dip type, spray type, splash type, top roll type (single-stage, multi-stage), side roll type, below roll type, etc. according to the liquid feeding methods. These classifications are based on the trial for making materials adhere to the drum surface more uniformly and efficiently.

Scraper knife no pressing type and drum material of carbon steel with clad steel are available in accordance with its application.

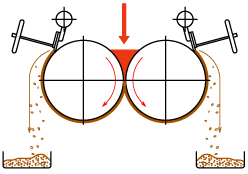

Double drum type

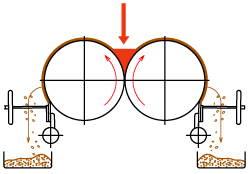

Twin drum type

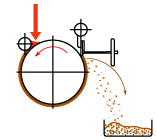

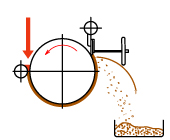

Single drum type

Model S-□□□□-SP

Model S-□□□□-DP

Model S-□□□□-BR

Model S-□□□□-TR

Model S-□□□□-SR

(Three-stage roll)

Model S-□□□□-MR

(1)D …Double drum type

T …Twin drum type

S …Single drum type(2)Drum diameter(3)Drum length(4)Feed system (indicated on the single drum type)

Example) “Double drum type,” “Drum diameter ø1000,” “Drum length 2,000” → D-1020 type

Example) “Twin drum type,” “Drum diameter ø1250,” “Drum length 3,000” → T-1230 type

Main Features

- Operation is continuous, allowing products of stable quality.

- Drying time is short and materials are not exposed to high temperatures for a long period, making materials which are sensitive to heat possible to dry well.

- Drum dryers are devices which are rational in most to perform evaporation and drying at the same time.

- Because the drum dryer is a heat-transfer drying system, its thermal efficiency is better than that of the other type of dryers and it is very economical.

- Because no liquid is left inside at shutdown, processing is possible to the last one drop.

- Performance adjustment is easy to carry out extensively, allowing one person to manage several units.

- Cleaning in the dryer is simple, making a change of application easy.

Examples of actual results

| Beer yeast, pulp yeast, and microbial cell-related products |

| Animal or plant extract products |

| Special dye and high polymer compounds |

| Slurry or solution of inorganic/organic materials |

| Industrial waste water |

| Others |

Test machines

Before using the drum dryer, it is absolutely necessary to confirm the property of materials to be treated using a test machine.

We have test machines always available, of which specifications are indicated below, and we are ready to carry out a test as needed and present the plan of equipment.

Dimensions

| Drum size | φ400×500L |

|---|---|

| Surface area | 1.25 m2 (double type) 0.625m2 (single type) |

Material

| Drum | Special carbon steel + hard chromium plate (double type) SUS316L + hard chromium plate (single type) |

|---|

Type

Double, Twin, and Single Types, any of which is available to test.

Catalog download

- Drum Dryers -catalog

(PDF file format 2723 KB)