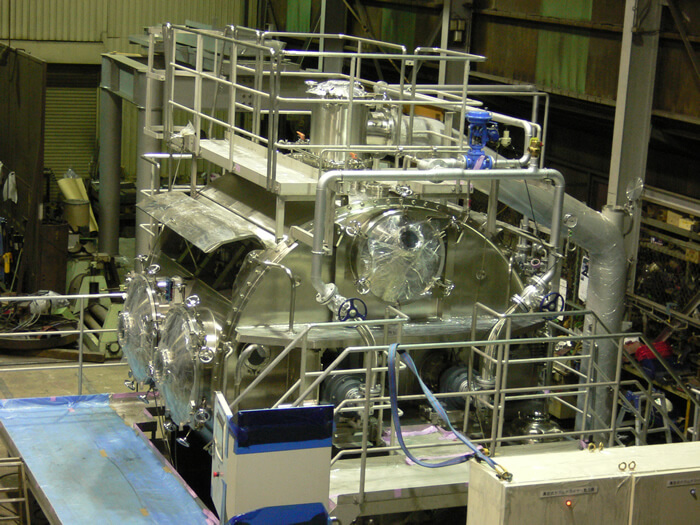

Dryers

Vacuum Drum Dryer

Features

- Vacuum drum dryer has the mechanism of the general atmospheric drum dryers, which is incorporated in the vacuum chamber, allowing continuous operation under the functional reduced pressure.

As a matter of course, devices accompanying the main unit play important roles because the dryer is operated under reduced pressure. Since drying is performed at low temperature, low-pressure steam or hot water is often used as the heat source.

Main Features

Based on the actual results and experiences on the drum dryers over the years, we have overcome the various problems on the mechanism that were difficult to solve by adopting a vacuum type. We have hereby completed the vacuum drum dryer system as an actual plant.

- Prevention of thermal decomposition and improvement of quality can be expected through low-temperature drying.

- Solvent can be recovered simultaneously with drying.

- Physical change of substances can be avoided thanks to the low temperature.

Test machine

Before using the vacuum drum dryer, it is absolutely necessary to confirm the property of materials to be treated using a test machine.

We have test machines always available, of which specifications are indicated below, and we are ready to carry out a test as needed and present the plan of equipment.

| Model | Double drum type |

|---|---|

| Size | ø160 × 200 L (surface area: 0.1m2 × 2 drums) |

| Operating pressure | 15 ~ 50 Torr |

| Rotation speed | 0.6 ~ 6rpm |

| Motor | 0.4 kW cyclo-speed reducer (inverter control) |

| Material | SUS304 + hard chromium plate |

| Heat source | Steam or hot water |