Dryers

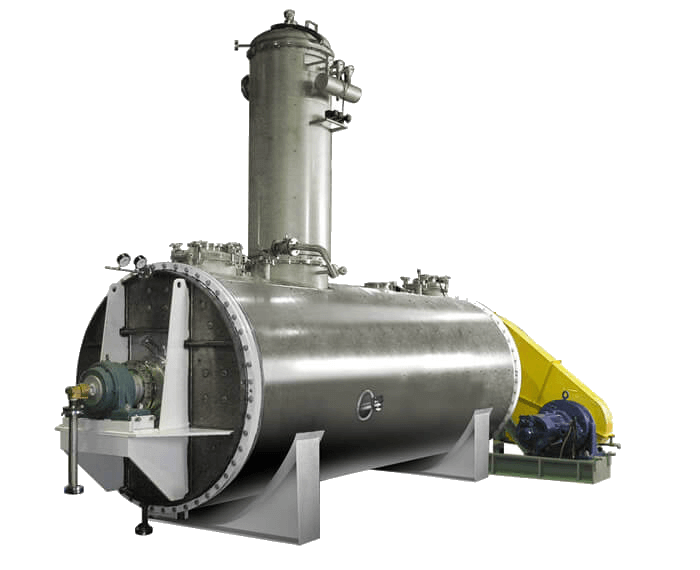

Vacuum Agitating Dryer

Features

- Vacuum drum dryer has the mechanism of the general atmospheric drum dryers, which is incorporated in the vacuum chamber, allowing continuous operation under the functional reduced pressure.

As a matter of course, devices accompanying the main unit play important roles because the dryer is operated under reduced pressure. Since drying is performed at low temperature, low-pressure steam or hot water is often used as the heat source.

Main Features

- Since drying is performed under vacuum, temperature difference between the heat-transfer area and treated material can be large.

- Since the treated material directly contacts the heat-transfer surface while it is being agitated and crushed, uniform dried products can be obtained efficiently.

- Since it can be operated under high vacuum (low temperature) by selecting a shaft sealing type, it is suitable for drying materials which are subject to air oxidation or deterioration by high temperatures.

- It can be used for materials whose vapors have hazardous properties or solvents.

- Flying of powder is fewer compared to the hot air drying method.

- Hot water, steam, and heat-transfer oil can be used as the heat source.

- When handling materials which are easy to adhere and become a dough or massive form, the drying speed can be accelerated and the rotational resistance can be reduced by inserting a ball or round bar.

Test machines

Test machines specifications

| Model | Special paddle type (Kantaro vane)) |

|---|---|

| Dimension | φ300×500L |

| Capacity | 20 liters |

| Material | SUS316 |

| Heat-transfer area | Jacket 0.34 m2 Shaft, vane 0.45 m2 |

| Working pressure | Vacuum in the drum |

| Shaft rotation speed | 10 ~ 40rpm |